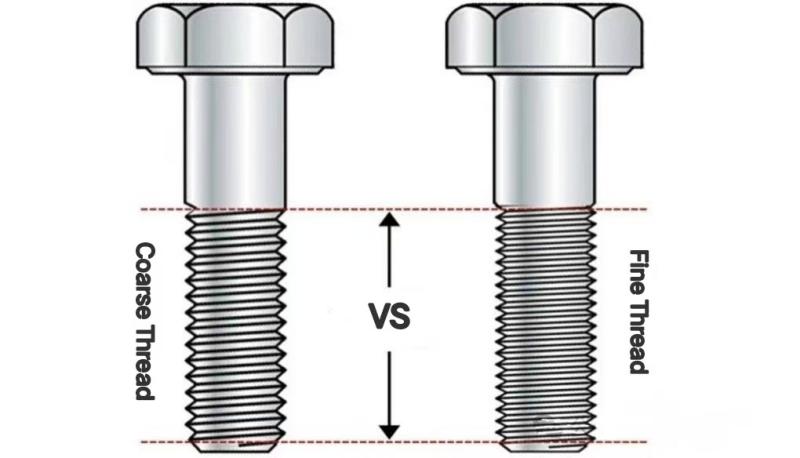

In daily life and industrial production, stainless steel screws play a crucial role as key components for fastening connections. It has a wide variety of types, not only reflected in the diversity of head and groove shapes, but also in the fine differences in thread design, especially the significant differences between coarse thread and fine thread.

Stainless steel coarse thread screw: a solid and durable example of coarse thread. As a synonym for standard thread, its specifications are clearly recorded in national standards and it is the most common thread type on the market. This type of thread is known for its high strength and good interchangeability, which can withstand large tensile and shear forces, making it highly favored in situations where high-strength fastening is required. In addition, the processing and installation of coarse thread are relatively simple, which can effectively improve production efficiency.

However, due to its relatively weak self-locking properties, anti loosening devices such as spring washers or locking nuts need to be used in vibration environments to ensure the stability of the connection.

Stainless steel fine thread screw: The small pitch and low tooth height of fine thread make it exhibit extraordinary potential in applications with limited space or requiring precise adjustment. Fine thread is also an ideal choice for thin-walled parts and parts with high anti vibration requirements due to its small footprint. However, the fragility of its threads also requires attention to avoiding collisions and excessive tightening during use, in order to prevent thread damage and affect the smooth progress of installation and disassembly.

Selection and application: For occasions that require high-strength fastening and good interchangeability, coarse thread screws are undoubtedly a better choice; For applications with limited space, precise adjustment, or high vibration isolation requirements, fine tooth screws are more capable. In addition, factors such as the adaptability of materials, the vibration situation of the working environment, and the convenience of maintenance also need to be considered.

Post time: Aug-19-2024